Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: top leader

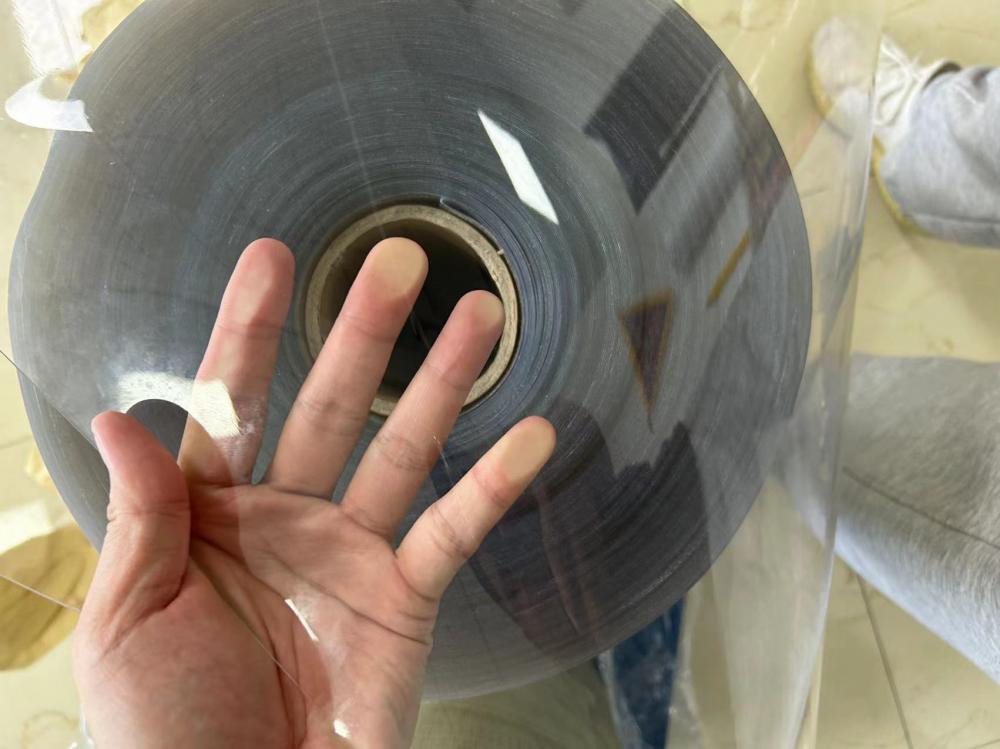

Material: Laminated Material

Types Of: Stretch Film, Shrink Film

Use: Packaging Film

Special Performance: Moisture Proof

Hardness: Rigid

Processing Technology: Casting

Place Of Origin: China

Transparency: Transparent

Packaging: standard

Productivity: 1000 tons per month

Transportation: Ocean,Land,Express

Place of Origin: Shandong

Supply Ability: 2000 tons per month

Certificate: ISO,SGS, GB.

Port: Qingdao port,Shanghai port,Tianjin port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Polylactic Acid (PLA) is different than most thermoplastic polymers in that it is derived from renewable resources like corn starch or sugar cane. Most plastics, by contrast, are derived from the distillation and polymerization of nonrenewable petroleum reserves. Plastics that are derived from biomass (e.g. PLA) are known as “bioplastics.”

Polylactic Acid is biodegradable and has characteristics similar to polypropylene (PP), polyethylene (PE), or polystyrene (PS). It can be produced from already existing manufacturing equipment (those designed and originally used for petrochemical industry plastics). This makes it relatively cost efficient to produce. Accordingly, PLA has the second largest production volume of any bioplastic (the most common typically cited as thermoplastic starch).

There are a vast array of applications for Polylactic Acid. Some of the most common uses include Plastic films, bottles, and biodegradable medical devices (e.g. screws, pins, rods, and plates that are expected to biodegrade within 6-12 months). For more on medical device prototypes (both biodegradable and permanent) read here. PLA constricts under heat and is thereby suitable for use as a shrink wrap material. Additionally, the ease with which Polylactic Acid melts allows for some interesting applications in 3D printing (namely “lost PLA casting). On the other hand, its low glass transition temperature makes many types of PLA (for example, plastic cups) unsuitable to hold hot liquid.

Polylactic Acid is principally made through two different processes: condensation and polymerization. The most common polymerization technique is known as ring-opening polymerization. This is a process that utilizes metal catalysts in combination with lactide to create the larger PLA molecules. The condensation process is similar with the principal difference being the temperature during the procedure and the by-products (condensates) that are released as a consequence of the reaction.

Now that we know what it is used for, let’s examine some of the key properties of Polylactic Acid. PLA is classified as a “thermoplastic” polyester (as opposed to “thermoset”), and the name has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at their melting point (150-160 degrees Celsius in the case of PLA). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics like Polylactic Acid liquefy, which allows them to be easily

and then subsequently recycled. By contrast, thermoset plastics can only be heated once (typically during the injection molding process). The first heating causes thermoset materials to set (similar to a 2-part epoxy) resulting in a chemical change that cannot be reversed. If you tried to heat a thermoset plastic to a high temperature a second time it would simply burn. This characteristic makes thermoset materials poor candidates for recycling. PLA falls under the SPI resin identification code of 7 ("others").

Company profile:

Shandong Top Leader Plastic packing Co.,Ltd was established in November, 1999. As a large-scale private enterprise with more than 500 staffs, our company is a major market player in plastic film and film manufacturer at North China. Our company pursues "people oriented policy" in human resource management and persists in applying "realistic approach, innovative mentality, quality consistency and efficient administration" as our core value. Strong technical force, advanced production equipment, our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply products of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane pressing film, etc. Totally 64 production lines, and the production of pvc sheet, PE sheet,pet sheet, Petg Sheet, GAG sheet ,PP Sheet, PS Sheet ,PC sheet ,pla sheet ,Biodegradable material film and Composite Plastic Film widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging , Handicraft packaging and other fields.

All of our quality management is complied with ISO9001-2008 Quality Assurance Certificate and SGS Quality Assurance Certificate . We also apply "customer first, satisfaction service" to provide a comprehensive process service value on our products. As a result our products have covered all over the world market. We sincerely welcome customers and friends from home and abroad for exploration and instruction, to establish extensive cooperation and to create brilliant future together.

Packing and Delivery:

PE FILM INSIDE + KRAFT OUTSIDE+PALLET

Our company adopts the protection angle of the paper shell imported from Taiwan, which can ensure the integrity of the goods to the maximum extent in the transportation process.

Paper tube Core:76MM

Paper tube thickness: 10mm

Paper tube port: No burrs and shredded paper are allowed. It is not allowed to stick with tape. Both ends of the paper tube are flush with the product.

We stipulate that the export packaging must use bullskin paper + PE film, the appearance of packaging tape, and the use of anti-folding packaging to minimize the impact damage of products in transit, and increase the annual packaging cost of nearly 200,000 yuan.

FAQ:

Q1:Could I have prices of your products?

A1:Welcome. Pls feel free to send us an email here. You will get our reply in 24 hours

Q2:Can we print our logo/website/company name on products?

A2:Yes, please advise the size and Pantone Code of the logo.

Q3:What's the lead time for regular order?

A3:10-21 days for order quantity lower than 50000KGS; For more quantity, usually 30 days.

Q4:Can I get a discount?

A4:Yes, for the order quantity more than 500 pcs, please contact us to get the best price.

Q5:Do you inspect the finished products?

A5:Yes, each step of production and finished products will be came out inspection by QC department before shipping.

Product Categories : PLA/polylactic Acid Film

Mr. Liu

Tel:

86-0533-2802680

Fax:

86-0533-2802680

E-mail:

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.