Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

On a: Male, born in 1962, Doctor of Science, associate professor 71994-2015ChinaAcademic atmosphere over the PVC resin is zui early development of thermoplastics. It has the characteristics of being difficult to burn, high mechanical properties, low price, rich source of raw materials, and mature manufacturing technology. However, it still has some shortcomings that are difficult to overcome. Poor thermal stability is one of its outstanding shortcomings. Hydrotalcite is a type of layered inorganic material with broad application prospects. The typical hydrotalcite compound MgsAKOHCOalOzui was discovered by Circa in Sweden in 1842. Its structure is very similar to that of brucite Mg(OH) and is composed of MgO6 octahedron. The shared ribs form a unit layer, and the Mg2+Al3+OH layer on the layer is positively charged, and the exchangeable anion COt between the layers is balanced with the positive charge on the layer, making this structure electrically neutral. Due to the specific structure and properties of hydrotalcite, hydrotalcite as a heat stabilizer for PVC resin has good application prospects. In 1980, the Japanese Kyowa Chemical Company took the lead in filling PVC with hydrotalcite as a heat stabilizer. However, the research on hydrotalcite and organotin as co-heat stabilizer is rarely reported. In this paper, organotin and hydrotalcite are selected as co-heat stabilizers, which is in line with the development trend of PVC resin heat stabilizers to non-toxic and safe, and it is practical to replace some more expensive organotin heat stabilizers with part of hydrotalcite in industrial production. significance.

1 Experimental part 11 Main raw material PVC resin, SG-5 type, Beijing Second Chemical Plant; Organotin (thiol) 8831, Beijing Third Chemical Plant; Stearic acid C18H35O2, analytical grade, Beijing Qiuxian Chemical Reagent Factory; Acrylic ester Class (ACR), industrial products, Suzhou Amway Chemical Plant; hydrotalcite, Mg/Al=2, self-made by our school; solid rock compensation, industrial products, Beijing Yanshan Petrochemical Company.

1.2 Experimental equipment high-speed mixer, GH-10D type, Beijing Plastic Machinery Factory; double-roller plastic mixing machine, SK-160B, Shanghai Rubber Machinery Factory; differential thermal balance, PCT-IA type, USA; Brabemder torque rheology Instrument, the preparation of PLV-1.3 material 1.31 mixing The components are mechanically stirred by high-speed hot mixing, and the order of addition is the stabilizer organotin 8831, the lubricant stearic acid and paraffin, and the processing aid ACR. When the stabilizer is added The temperature rise is 50-60 C, and the temperature rise when the lubricant is added is 70-80. The temperature rise when the processing aid is added is 90-100°C. When the mixing is completed, let it cool and remove it at 35- 40C discharge. The mixture is used as the test sample of Brabender torque rheometer and further masticated.

2 Plasticizing: The above-mentioned mixture is plasticized in a two-roll mixer, and the temperature is controlled between 165-170C. During the repeated plasticization of 8-10mim, the roller distance is from small to large, and then from large to small. The sample is well plasticized, and finally the sample is pressed into a thin sheet of about 1mm thick to sample.

1.4 Test 1.41 Thermal stability time According to the GB881588 standard, cut the PVC sheet into fine particles with a side length of 2mm, put the particles in a test tube, put a Congo red sample strip in the specified position, seal the test tube mouth, and place it in a glycerin bath , Observe the discoloration time of the Congo red sample strip at a temperature of (200 ± 2) C. The time when the sample strip just starts to change color is the thermal stability time.

2 Thermogravimetric analysis Thermogravimetric analysis can be used to characterize the thermal decomposition temperature of materials. The instrument used is a PCT-IA thermogravimetric analyzer. The total mass of the product at the actual heating rate is about 20mg, and the measuring temperature range is 50~700C. The thermal weight loss curve of the sample is measured. Since the initial decomposition temperature is not easy to determine, the temperature at 1% weight loss is used instead.

2.2 The influence of different hydrotalcite content on PVC processing performance The balance torque value of PVC materials with different hydrotalcite content in the Braben-der torque rheometer under constant speed rotor agitation was tested.

The lower the value, the better the liquidity. The results are shown in Table 1. Table 1 The equilibrium torque value w (hydrotalcite)/% equilibrium torque of PVC materials with different hydrotalcite content.) Journal of Beijing University of Chemical Technology. Schematic diagram of the thermal stability mechanism of hydrotalcite in PVC. The addition of P has a certain effect on the flow and processing performance of the material. When the hydrotalcite is 1% to 2%, the fluidity and processing performance of the material are the best. This is because after the hydrotalcite is added, it is embedded between the long PVC chains during the processing. When the material is plasticized and flows, the viscosity of the long PVC chains decreases and fluidity increases due to the barrier of the hydrotalcite, while the hydrotalcite itself is layered The structure also makes it have a certain degree of lubricity, which improves the processing performance of the material. When the content of hydrotalcite further increases, the contact probability of hydrotalcite particles increases, and they shear each other during flow, which in turn increases the viscosity of the material and deteriorates fluidity.

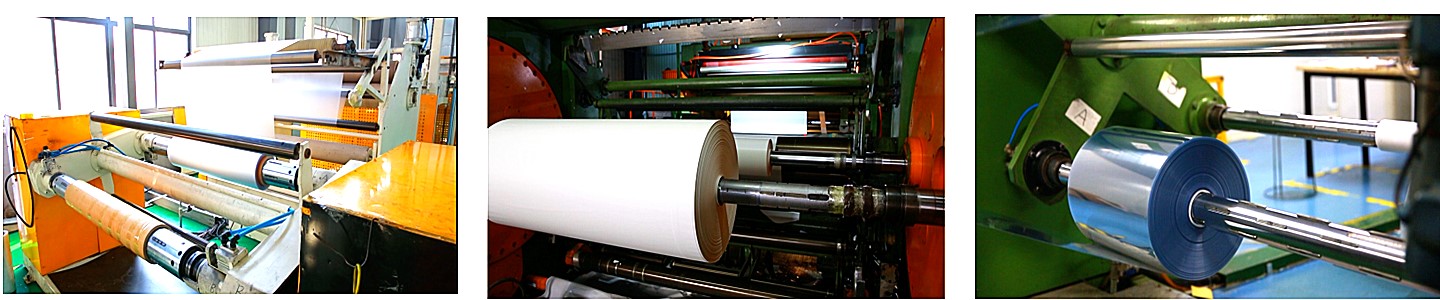

Shandong Top Leader Plastic Packing Co.,Ltd was established in November, 1999. As a large-scale private enterprise with more than 500 staffs, our company is a major market player in plastic film and film manufacturer at North China.

Our company pursues "people oriented policy" in human resource management and persists in applying "realistic approach, innovative mentality, quality consistency and efficient administration" as our core value. Strong technical force,

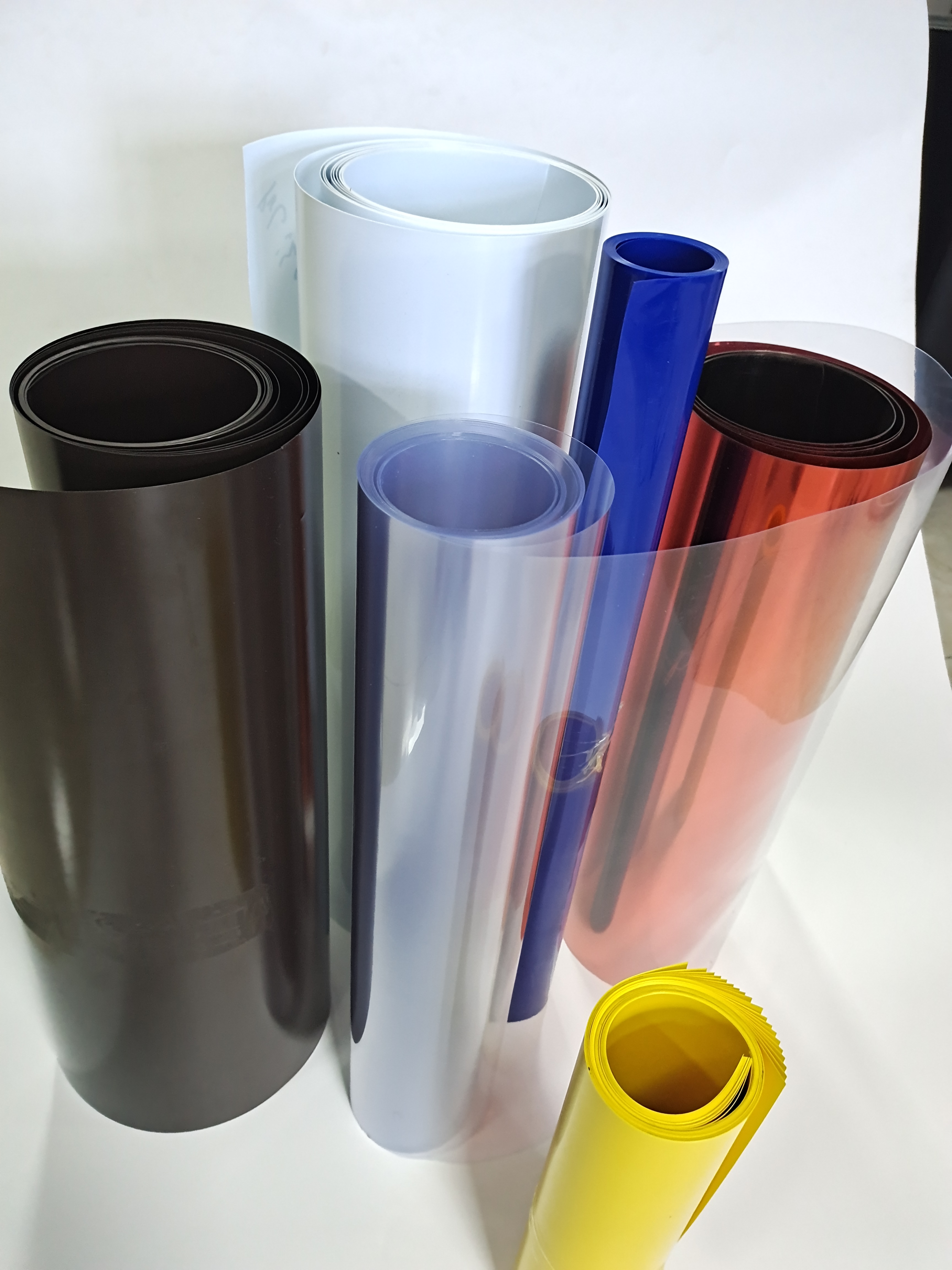

advanced production equipment, our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply products of common transparent film, super transparent film, electrostatic protective film,

inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane pressing film, etc. Totally 64 production lines,

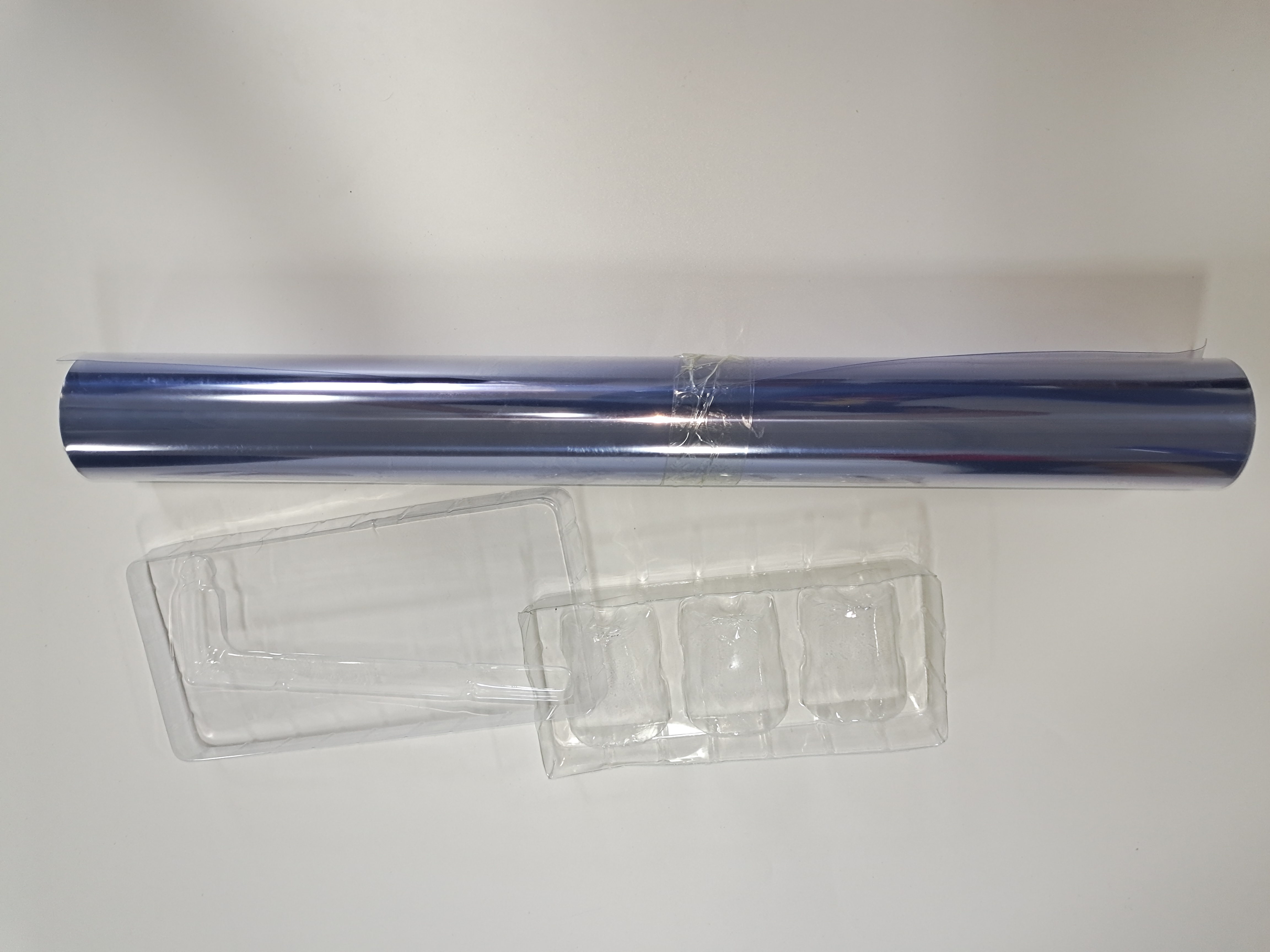

and the production of PVC sheet, PET sheet, Petg Sheet, GAG sheet ,PP Sheet, PS Sheet ,PC sheet widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging , Handicraft packaging and other fields.

All of our quality management is complied with ISO9001-2008 Quality Assurance Certificate and SGS Quality Assurance Certificate . We also apply "customer first, satisfaction service" to provide a comprehensive process service value on our products.

As a result our products have covered all over the world market. We sincerely welcome customers and friends from home and abroad for exploration and instruction, to establish extensive cooperation and to create brilliant future together.

Mr. Liu

Tel:

86-0533-2802680

Fax:

86-0533-2802680

E-mail:

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.