Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

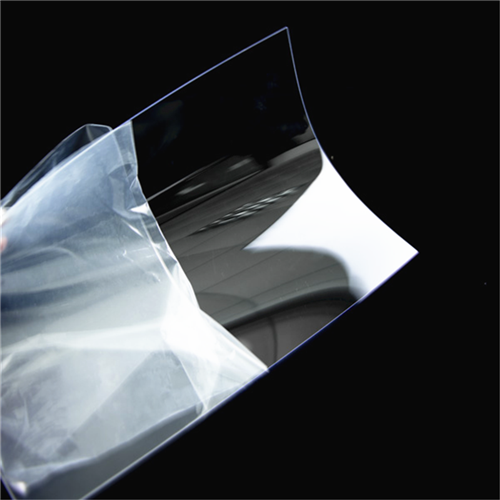

Common quality problems and solutions in PET sheet production

The PET SHEET produces crystal point impurities. The reason is that the raw material, PET sheet does not produce crystal point impurities. However, impurities or inferior raw materials introduced during the processing due to drying problems and environmental problems lead to the production of crystal point impurity horizontal lines and water lines (orange peel) during the sheet forming process. Wire).

Water marks are caused by the material flowing out of the PET sheet extruder die into the calender roll. Because there is no remaining material, the material is not compacted and the sheet surface shows poor smoothness like orange peel. The solution is that there must be residual material visible to the naked eye between the calender rollers, and the residual material rotates evenly. Horizontal lines are a process defect of the extrusion method, just like the water ripples of the calendering method. They are indentations caused by the speed difference between the two calender rollers. The solution is to improve the accuracy of the three-roller speed regulation of the three-roller calender and at the same time improve the accuracy to reduce horizontal lines.

PET sheets have yellowing, black spots or impurities, streamlines, and uneven calendering. The main reason for bubbles in the sheet is that the pellets are not completely dry and the moisture content exceeds 0.005%. If moisture is not sufficiently dried, it will penetrate deep into the slice, indicating the formation of molecular bonds or remain trapped deep in the slice. If the drying temperature is too low or the time is too short, the drying effect will be affected. When blisters appear on the sheet, the drying temperature and time should be adjusted immediately. The main reason for the yellowing of the paper is that the drying temperature is too high or the time is too long. The main reason at this time is The measure is to lower the drying temperature and shorten the drying time. Another reason for the yellowing of the sheet is that the melt temperature is too high. At this time, the melt temperature should be quickly lowered. The main reason for the black spots and impurities in the sheet is that the filter is damaged or the PET is extruded. PET decomposition products remaining in the outlet.

Contact email: sale@sdzlplastic.com

Mr. Liu

Tel:

86-0533-2802680

Fax:

86-0533-2802680

E-mail:

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.