Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

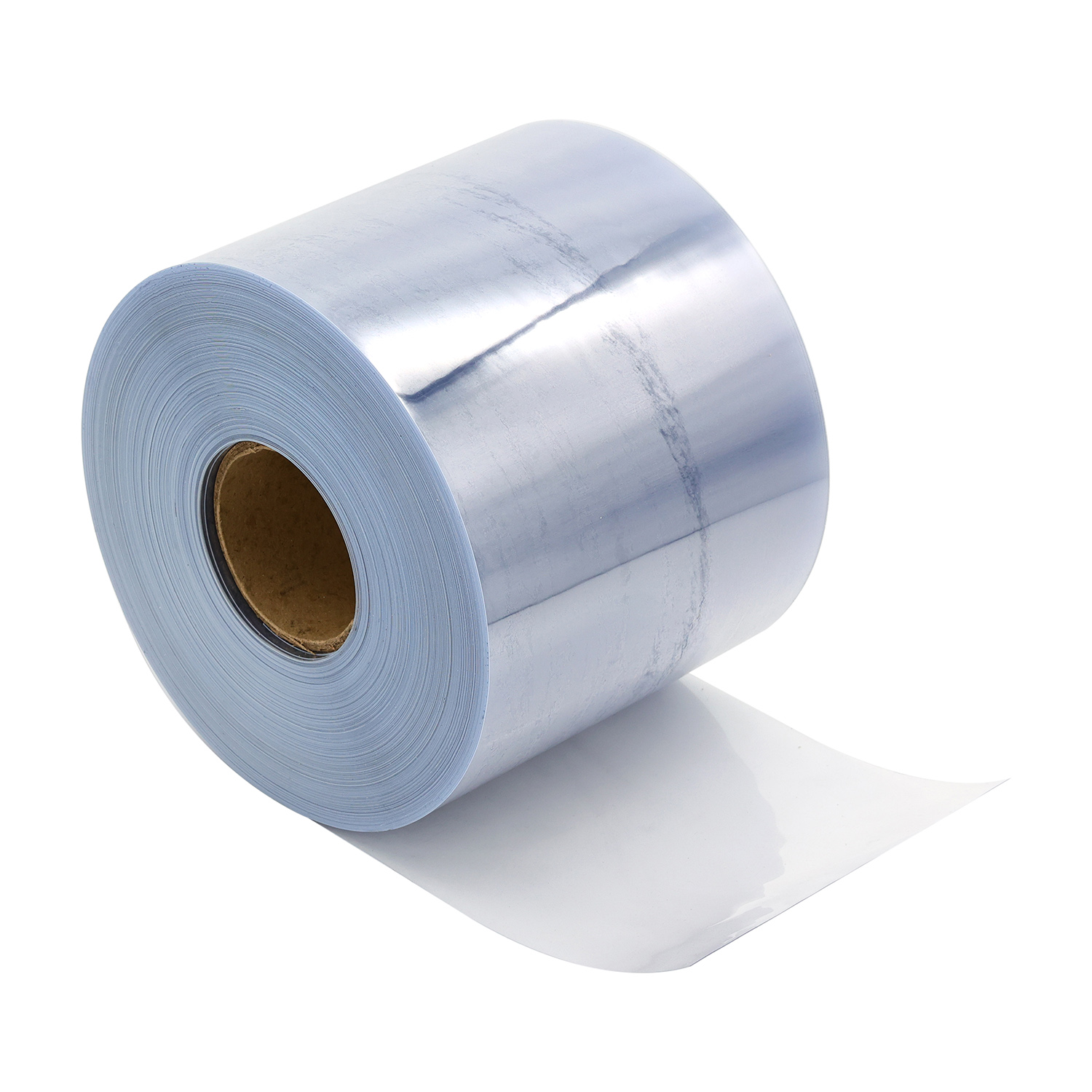

PVC sheet (polyvinyl chloride) is a flame retardant material with good chemical stability and only produces low tensile cracking internal force. The material's properties also include high strength, high stiffness and hardness, an operating temperature range of -15 degrees to 60 degrees, and it can be welded.

PVC sheet features:

① Strong corrosion resistance: suitable for anti-corrosion equipment in the chemical industry.

②Easy to process: cutting, welding, and bending are all very simple.

③High strength, high stiffness and high hardness;

④Good electrical insulation;

⑤Good chemical stability; self-extinguishing;

⑥Low water absorption; easy to stick and paint;

⑦The price is relatively low.

PVC sheets film are widely used in food, gifts, clothing, electrical hardware, handicrafts, toys, daily necessities, educational experimental supplies, medical and health supplies, travel products, electrical appliances, electronic original gas parts, agricultural products, auto parts, anti-theft locks and other blister, Compression molding, Folding Box packaging, stationery production, printing, etc.

PVC sheets roll have good chemical stability and acid and alkali resistance. In addition, other advantages of PVC sheets are mainly reflected in the following aspects:

① Good light transmittance, the total light transmittance of the new film is greater than 85%; the light transmittance of crop light is small, only 20% of the 0.3m wavelength passes through, so it is often the material of choice for PVC Plastic bags, while polyethylene (PE) greenhouse film After the light condenses through the 60% button-type shed film, the impact on the light transmittance is smaller than that of the PE shed film. However, after a period of use, the light transmittance decreases due to the precipitation of plasticizer and adhesion of dust.

②Good moisture, small thermal conductivity, especially at night, the surface wave radiation transmittance of 6 to 15 meters long is very small, only 20% for PVC plastic bags (more than 70% for polyethylene shed films), the average temperature of the flow and the ground temperature are 1.23 ℃ and 1.05℃ respectively higher than polyethylene shed film.

③Good air tightness, the air permeability of nitrogen, oxygen and carbon dioxide are 3.0, 9.0 and 75 (10-14cm3/mmcm2SPa) respectively, but the air permeability of water vapor (6.9103g/mm24hm2Pa) is better than the LDPE film.

④High tensile strength, good ductility and strong wind resistance.

⑤Good weather resistance, generally PVC cosmetic bags can be used for more than 1 year.

⑥Good welding and bonding, easy to splice and repair.

Mr. Liu

Tel:

86-0533-2802680

Fax:

86-0533-2802680

E-mail:

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.